-

Posts

644 -

Joined

-

Last visited

-

Days Won

130

Content Type

Forums

AutoShopOwner Articles

Downloads

Blogs

Gallery

Profiles

Events

Store

Links Directory

Shop Labor Rates

Community Map

Everything posted by Transmission Repair

-

Your advice is a sound strategy. However, a lot of younger techs who become shop owners may not agree. Our industry needs people like you, who also train. Keep doing what you do. Invaluable advice.

- 7 replies

-

- 2

-

-

- labor

- labor rate

- (and 6 more)

-

If I could call just one automotive article a complete seminar, this would be the article. It was a very good article with some absolutely great books to read. https://www.ratchetandwrench.com/shop-life/columnists/article/33006771/bennett-10-must-read-books-for-auto-repair-shop-owners

- 1 reply

-

- 1

-

-

Some Comedy videos to brighten up your day...

Transmission Repair replied to bantar's topic in Non-Automotive Discussions

1:06 -

I don't believe in the flat-rate system. We paid by the clock hour. Unless the transmission issue was obvious, I usually did the diagnosing myself. I was the most experienced tech in our shop and was deathly afraid of misdiagnosis if I didn't diagnose it myself. One job stands out in my mind. THE STORY: We had an AWD Audi towed into the shop for no movement. We were busy and my lead tech diagnosed it as a major transmission problem. After removing and disassembling the transmission, he could find no cause for the no movement condition. He found only normal wear and tear for a 150K mile transmission. That scared the crap out of me as I was thinking I should have diagnosed the problem. We did the normal R&R and rebuild with no hard parts. After the transmission was installed back in the vehicle there was still no movement. I got into the vehicle on the lift and noticed the speedometer was registering speed, but as soon as we lowered the vehicle on the ground, still no movement, but the speedo said it was. Long story made short; the right front axle had stripped where it goes into the front diff. We replaced the axle and all was good. That was a phone call I didn't want to make. I called the customer up and explained what happened. He was fairly savvy because he was a diehard Porsche-Audi fan. I was going to seriously reduce the price due to our error, but he asked about our 5yr./100K warranty. I said for the reduced price, I could only offer a 12mo./12K mile warranty. He was emphatic about getting the longer warranty. In the end, he agreed to pay full price to get the longer warranty. Feeling bad about the misdiagnosis, we ate the axle and labor. That's one of the reasons I like to diagnose transmission problems myself. It seemed obvious to my tech at first, but his mistake almost cost me a job, and a customer.

-

With automatic transmission repair, part prices aren't easily looked up online like G/R is. What our customers looked at was our bottom line. The few that did look up part prices online would look up the price of a complete transmission and weigh that compared to what we charged. We rarely had an issue with our prices, although we got top dollar for what we did.

-

Alignment Machine Jan 2024

Transmission Repair replied to Hands On's topic in Automotive Shop Tools & Equipment

Concerning a new shop location, listen to, or read... https://www.mondaymorningmemo.com/newsletters/follow-the-sound-of-bulldozers/ Read my other posts about selecting a good location. "Expensive rent is the cheapest advertising you can buy." -

Some Comedy videos to brighten up your day...

Transmission Repair replied to bantar's topic in Non-Automotive Discussions

HUMOR AT ITS FINEST!... (2:14) -

Dirty Tricks: Rising Credit Card Junk Fees

Transmission Repair replied to bantar's topic in Credit Cards, Payments, Financing

This is a quote of mine from another post I made... There were several items I "buried" in either parts, labor, or both because listing them separately would raise eyebrows. Items like... Shop supplies Waste oil disposal Towing (because we advertised free towing) Chemicals Gas in customer's cars Credit/Debit card fees and other incidentals... were never listed separately, but the customer did pay. I never had a problem doing it that way." -

We didn't have too much of a problem with parts because we were a transmission repair shop. The few times I did run into an inordinate amount of time for locating a part, I didn't charge extra per se. What I did was to increase the markup in most hard-to-find parts. Nobody ever complained. There were several items I "buried" in either parts, labor, or both because listing them separately would raise eyebrows. Items like... Shop supplies Waste oil disposal Towing (because we advertised free towing) Chemicals Gas in customer's cars Credit/Debit card fees and other incidentals... were never listed separately, but the customer did pay. I never had a problem doing it that way.

-

Technician Production is More Complicated than You Think

Transmission Repair commented on Joe Marconi's blog entry in Joe's Blog

I found this article in Ratchet & Wrench magazine and it made me think a little differently. -

Dirty Tricks: Rising Credit Card Junk Fees

Transmission Repair replied to bantar's topic in Credit Cards, Payments, Financing

Well, I guess I'm wrong about charging extra for plastic. We recently received our property tax notice and they charge extra for paying our property tax with plastic. They call them "bank fees" and charge 2.45% for credit cards and 1% for debit cards. -

Dirty Tricks: Rising Credit Card Junk Fees

Transmission Repair replied to bantar's topic in Credit Cards, Payments, Financing

I would trust your research a lot more than my 8-year-old dated experience. Using your 1.83% figure, we would have been paying about $1982.50 per month. Charging extra for plastic goes against the written merchant agreement. I believe you have the best idea for covering the cost in the shop labor rate. Good job on the research! Thank you. -

Dirty Tricks: Rising Credit Card Junk Fees

Transmission Repair replied to bantar's topic in Credit Cards, Payments, Financing

That was about 10 years ago before we sold our shop and retired. We are doing similar figures in plastic sales. We were grossing about $1.3-$1.2 million a year in sales in the last 3 years we were in business. $1.5 million with our processor would be about $7.5K/yr. You're paying what works out to about 2% while we were only paying half of 1%. $2,500/mo. X 12 = $30K. $30K divided by $1.5 million = 2%. I would think you are paying a higher rate because your average sale is much smaller and more numerous than ours. We only wrote about 80-90 tickets a month, but they were often really big tickets. Perhaps things have changed in the last 8 years since we sold our shop, I don't know. But judging from Bantar's posts from 2018 at the beginning of the thread, he was paying even less. -

Dirty Tricks: Rising Credit Card Junk Fees

Transmission Repair replied to bantar's topic in Credit Cards, Payments, Financing

Things are constantly changing over time when it comes to payment. Who pays by cash or check anymore? Few, if any. 99% of our invoices were paid with plastic. Because we were a transmission repair shop, our average sale was over $1.5K. We shopped around at first but finally settled on a company that charged us .5%. (I can't remember who.) With the annual volume we were doing, that still worked out to about $500/mo. -

Slow or Non-Paying Customers

Transmission Repair replied to BNC173's topic in Credit Cards, Payments, Financing

I, too, used to extend credit in my early transmission repair career and it didn't work for me. 30 years, 3 locations, and 2 states later, I learned a new method. I bought an expensive location in an affluent neighborhood with high visibility and traffic count. I also tried to specialize in 10-year-old and newer vehicles. I never had a payment problem at that location. The customer either had a debit or credit card available. Would we refuse to work on older vehicles? No, I just didn't turn on the sales charm and sometimes asked for a parts deposit. I never got beat out of money at that location. Was it a cheap solution? No, not at all. Between the mortgage and PPC advertising online of $13K/mo. it was (to me) the cost of admission to a hassle-free financial situation. -

Warranty - when are techs responsible?

Transmission Repair replied to Gerald Martin's topic in General Automotive Discussion

I don't know what to tell you, Gerald, each shop is different. I can tell you how I handled it. I was a transmission builder long before I became a transmission shop owner so my method of handling comebacks is different. Before I start, let me tell you this. I worked at a lot of transmission shops that were franchises, independents, and even a dealership. Something pervasive to me was most of them couldn't keep me busy all the time. I remember distinctly the week between Christmas and New Year's of 1981 when I was at a Chevrolet dealer; I took home $81 and I'll never forget it. I felt they were lacking in marketing, sales, or both. When I became a transmission owner, that all changed. I didn't pay flat rate, but by the clock hour. If we had a comeback or a no-go that failed the final road test, they were paid again. I don't care if it was a defective or mismatched part or even the technician's mistake I paid them. They could always depend on getting at least 40 hours a week. Because few shops do that, the techs would go the extra mile. They would sometimes beat themselves up for mistakes or the other techs would think less of them. Peer pressure ended up being a great equalizer. The poor techs I would let go. The way I see it, marketing and sales were my job as a shop owner. The very first year I was in business, I bought a full-page Yellow Page ad. (back in the day) I later transitioned that to online Pay-Per-Click advertising. I spent A LOT on marketing and a lesser amount on comebacks, but I still always paid. It was incumbent on me to structure our prices to cover those costs. We were the highest-priced transmission shop in the area; equal or higher than the dealer. Transmissions are a transaction-based business, not relationship-based like most shops. So be careful of your pricing structure. Our business was a lot like the collision business; one and done. Move on to the next job. A repeat customer to us was either a comeback or somebody with multiple vehicles and really bad luck. 🙂 So, take everything I've said with a grain of salt. It worked for me very well over the years. I did a little bit of shop coaching/managing after I retired and the almost universal problem I saw the most was undercharging for their services. In other words, giving work away. The other problem I saw was after my engagement was over, that shop would go right back to doing the same thing as before, forgetting everything I had done and taught them. I guess old habits are hard to break. When the shops starve, the techs starve. Trickle-down economics. I hope and pray you work your way out of the comeback issues. -

As with all things in this industry, with time, effort, and gaining experience, we get better at it. I ran across a great marketing post in the Parts Tech blog about marketing. It gives a step-by-step recipe for developing a marketing program from scratch for beginners. Here's the article---> https://partstech.com/blog/auto-repair-shop-marketing/

-

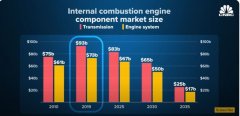

Even though I like the Electric Vehicle (EV) future in theory, putting it into practice is going to be difficult. In my view, there are more cons than pros at the current time. However, given the time, the pros will outweigh the cons. The whole reason there are more negatives than positives at the current time revolves around politicians thinking the EV conversion is going to be simple, like throwing a switch. Nothing could be further from the truth. Battery technology, sourcing raw materials, gearing up assembly lines, and retraining assembly line workers are all challenges to be dealt with long before EVs can be sold en masse. Tesla is currently leading the pack when it comes to EV adoption, although they still have their challenges. In my view, politicians are trying to ram EV adoption down our collective throats way ahead of what’s possible. Thank goodness they are starting to get their wits about them and the U.S. House of Representatives has recently voted against the proposed federal EV mandate. (See: Ratchet & Wrench article) The transition to EVs is going to be long, slow, and hard, unlike what the Biden administration currently thinks. Furthermore, I think the typical automotive shop that makes heavy investments in EV diagnosis and repair (other than routine maintenance) is quite a bit premature. Shops are already equipped and trained for routine maintenance. Leaving the heavy diagnosis and repairs to the places that sell the EVs in the first place, is my vote. I do believe that, over time, EV adoption will take place. However, it won’t replace conventional ICE-powered vehicles. ICE-powered vehicles will always be sold, albeit in lesser quantity. That will never go away. What’s your view on the ICE-to-EV adoption model? For, against, or indifferent? No matter the outcome, I feel very strongly our industry will adapt and never go away.