-

Posts

19 -

Joined

-

Last visited

-

Days Won

2

Scott Osborn last won the day on August 6 2018

Scott Osborn had the most liked content!

Business Information

-

Business Name

Osborns Automotive

-

Business Address

1001 South Pacific Coast Highway, Redondo Beach, California, 90277

-

Type of Business

Auto Repair

-

Your Current Position

Shop Owner

-

Automotive Franchise

None

- Website

-

Banner Program

None

-

Participate in Training

Yes

-

Certifications

ASE Master L1, AAA, AMI, ASA, SAE,

Recent Profile Visitors

3,037 profile views

Scott Osborn's Achievements

-

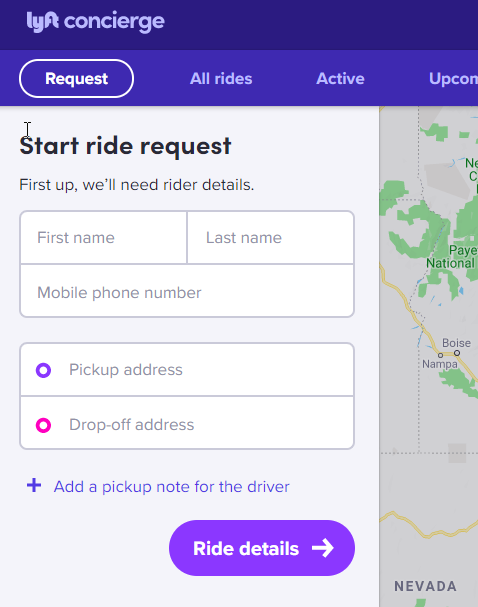

We use Uber and Lyft. We use their dashboards that allow the customer to get a text message when the car is coming, easy for return trips too. The customer has a text message that they click when they're ready to be picked up. Lyft is called their Lyft Concierge: https://www.lyft.com/concierge . The dashboard shows all of your rides you've ordered, costs, users, etc. Very handy to know exactly when your customer will arrive too! We stopped using Uber as the prices for "Surge" were getting out of hand.

-

Shop Owners: Can you ever unplug?

Scott Osborn replied to Joe Marconi's topic in Joe’s Business Tips For Shop Owners

I've reached that point in my life where I realize the value of unplugging. The shop is running great without me, often better... The unplugging used to take 4-5 days before I can relax and now I'm down to a quick 24hr period before that "Zen" point. This summer has pushed me to enjoy the time I have and let my employees run the business. They're rewarded for doing a good job & they make me proud. I've had several amazing vacations this year and looking forward to a few more. The latest was a week on the Houseboat in Lake Powell. I owe it to other owners and their wisdom, guys like Joe Marconi, Bob Cooper, Jim Murphy and many more who have taught me to release the bad customers, embrace the good and take care of the people that have a positive influence on you. Never be afraid of changing the way things are done! I talk to other shop owners on a daily basis and hear the same story, "That won't work in my shop", "My techs won't agree to that", etc.. Be the change, Lead them, Show them. It can be done. -

Courtesy Inspection Technician Pay

Scott Osborn replied to spencersauto's topic in Human Resources, Employees

We've been paying .5 for the inspection process. We also require as part of the inspection to look at not just the vehicle, but the previous inspection (if there is one) and any repair history for the past year. My guys do a great inspection and take their time to do it right. I guess it comes down to letting them know what your expectations are. The other benefit to paying for their time is that the shop owns the inspection at that point and we don't have to guarantee that the tech doing it will be the one getting the work. Using that idea, we also know that a tech will recommend work even if it's something they don't like to do as it may go to the guy that specializes in that area. If you have a tech that's not well versed in front end, he's not going to sell a difficult bushing job. But if he knows the other guy can do the work, he's more likely to give you an honest report. -

Scott Osborn started following Vin Code Scanner? , text messaging customers ? , Modern SOP platform for creating/implementing standard operating procedures? and 2 others

-

text messaging customers ?

Scott Osborn replied to sparkerauto's topic in Customer Experience & Reviews

I built a standalone texting application to use on my front counter with the PC (web based, no cell phone needed). Very simple, keeps in contact with the customer and gets immediate results. I'm going to make it available to other shop owners as soon as I get a few bugs worked out. What features would you consider important if you could add anything you wanted?- 19 replies

-

- texting

- text messaging marketing

-

(and 1 more)

Tagged with:

-

It's great for the digital assets. I have a friend that lives in Oregon, has a shop in Phoenix. He visits every few months and this is his mode of communication. All RO's are scanned and saved in a folder by RO number and can be accessed by any of the staff. I haven't gone to that yet as we already scan and trash ALL paper generated from the shop in a different way. It's been a great system so far and it's growing into an essential part of our routine. We're just getting started, but it's the go-to place for questions like "What days do we have off around Thanksgiving", and "Where's the vacation request form"? Their usage of it is being ramped up now and I suspect we'll be all-in by the first of the year with the shop calendar, online request forms for days off, etc.

-

I've got 7 users. 3 of us are on Microsoft Office 365 plans at $20 per month. It doesn't have to be that much but I wanted full Office versions (Legal ones) on my PC's that were updated with the latest versions at all times. The other 4 are on Microsoft Skype for Business plans at $2 per month per user. We use Skype for Business as our messaging system in the shop between all workstations. It also allows me to work a lot from home that way. I don't believe you need a paid MS account to view material on a Sharepoint site, as I can share with anyone I think. We are no putting all of our projects and documents in the plan, I can view, edit, create from any device and always synced. Sharepoint can also have customer facing info if you need it.

-

We've used WayWeDo (waywedo.com) for a couple of years, Works well, easy to manage. BUT.... Getting everyone to view it has not been ideal. So, I'm in the middle of making a move to Sharepoint. It's part of the Microsoft Office programs and allows creating, editing, sharing, syncing, etc with whoever you choose. Great security and ability to have multiple authors. I'm moving all my business files to it for storage and access in the cloud. Syncs to local pc's if I want it to and allows access from anywhere to work on it. My employees will be allowed to view certain sections of it that contain job descriptions, SOP's relative to them, vacation and holiday calendars, contacts, equipment info, MSDS, etc. My Manager will be able to access special management folders where we can make changes to the files the employees view as well as private sections for all our marketing info. Then there's another section for my wife & I that will have all bookkeeping, tax, contract info in it.

-

Almost done with ATI

Scott Osborn replied to Bob K's topic in Management Coaching, Business Training, Consulting

Bob, We "Graduated" from ATI in 2006 with the "Shop of the Year" award. Back then it was a 24 month agreement and then we added another 12 months as they started up their Mastermind Group. We learned a lot, it was a great experience and a real eye opener for my wife and I. I have a lot of good things to say about the program as it was 10 years ago. I haven't stayed in touch with them much since then. The only "Trouble" I can say to beware of when exiting, is to think that you're done learning and falling back on old habits. After we graduated, we were looking to move to the next level and knew that we still wanted to have someone hold our feet to the fire to keep getting better and not fall back on old habits. We tried RLO for a short time and then when Bob Cooper from Elite and Jim Murphy put together the PRO Service Program in 2008, we jumped in and have continued with them, I don't see leaving until I retire. The team of professionals is unsurpassed, their ethics and commitment to your success is always first, you're never left wondering what you paid for. As far as the level of shop owners, out of 90 shops, I haven't seen one dud. They go through a screening process that makes sure you're a good fit for the group and that they're a good fit for you. A very positive experience. Feel free to give me a call if you have any questions. -

Battery Impact Guns

Scott Osborn replied to flacvabeach's topic in Automotive Shop Tools & Equipment

As we do updates to our manual, the employees signature is only to show that they have read and received a copy. It does not state that they agree with it. If they disagree or don't follow it, that's a different story, also covered under the policies and procedures. As far as the torquing of wheels, our policy is that you don't get a second chance. ANYONE caught not torquing a wheel with a torque wrench will be terminated. No torque sticks allowed in the shop. I know it sounds harsh, but it is dealt with at the first interview with an employee and it is one of the few things that I demand 100% from my crew. I have a friend with a shop that was working on his friends daughters car. She was on the freeway and a wheel came off. She was able to gain control of the car and stopped in the fast lane. Another car came from behind and hit her. She died at the scene. So, in short, he killed his friends daughter. Imagine living with that the rest of your life. The day I heard that story, my policy took effect. We will not put our customers lives in danger over a few minutes of insuring 100% correctly torqued wheels. -

Vin Code Scanner?

Scott Osborn replied to Joe Marconi's topic in Management Software, Web Sites & Internet

There are several apps on the market that will scan the barcode on the VIN and then email it to you. The one I've used is for my android at https://play.google.com/store/apps/details?id=com.bees4honey.vinscanner I can scan the barcode, email it to myself and by the time I get to the PC to write up the RO, it's in my email inbox waiting for me to use it to cut and paste into the management program or parts lookup. As a side note, I'm developing a scanner app that will do just that and start an inspection in our Repair Shop Solutions inspection program. -

The software was designed to run independent of any management system so that everyone could use it. It's extremely fast, less than 20 seconds, if ALL of the information needed to be typed in. When you look at the time savings for the tech's and the advisors from getting complete information, that 20 seconds can save you easily 5 minutes or more. HOWEVER........ We realized the need to integrate with the management systems and are now installing a very small program on the users PC that will allow a single click to generate an inspection with all of the data filled in. We have also added the VIN decoder for those that do not have one of the major management systems as well as the system will fill in the data for returning customers. On a side note, we've seen some interesting new inspections popping up that shops are designing. The system lends itself very well to making "Checklists" for getting a tech to do testing in a specific order and not jumping to conclusions. Think of "Starting and Charging System", "Air Conditioning", "Cranks but No Start", and other checklists... I'm sure it's happened to almost every one of us, a 2005 Tahoe gets dragged into the shop and the tow truck driver has told the customer that the fuel pump needs to be replaced, the tech spends 5 minutes looking at it and tells the advisor to get him a fuel pump. Two hours later, with the new pump installed, the tech say's the coil must have burned up during all that cranking and now it needs a coil too. This embarrassing and very expensive problem could have been avoided if the tech had used a "No Start" checklist that asked some of the questions like "Fuel Pressure", "Cranking Amps", "Spark Quality", "Fuel Level", "Cranking Vacuum", etc. I'd be happy to set up a webinar for the users of this message board, then you can see it working with live data. Let me know if you're interested.

- 21 replies

-

- 1

-

-

- Mulitpoint process

- Workflow

-

(and 2 more)

Tagged with:

-

Harry, I'm going to make your day. First of all remember that I'm only a phone call away if you need help. (424) 262-1580. I just ask that you remember that I'm on the left coast, 3 hours behind you..... Even though a tech marks an inspection as complete by clicking the save button, you can still open it and make changes, it is not locked for editing. If you're having your S/A put the pricing into the system (I don't think you have it turned on, go to "SHOP INFO" to turn on pricing), it's much quicker if he goes right into the "RO Completion Report" and makes his changes/updates there. Just click the little plus sign on the left to open it up: Second, a VIN decoder is only going to save you a few seconds as you select the year/make/model. Since we're not getting engine info, trim info or much else, there wouldn't be much time saving. However, I hear you, and I can do one better. I will upload your shop's data to the site and all you have to do is drop in the VIN and the software will pull out the year/make/model/license/customer name & email for you if the customer has previously been in your shop. You will only have to input the new customers you get. And, I will work on putting a VIN decoder in the software for you. Contact me and I'll get you the info I need to get your data uploaded.

- 21 replies

-

- 1

-

-

- Mulitpoint process

- Workflow

-

(and 2 more)

Tagged with:

-

I've found the best way to get started is to get your advisors prepped and then take one of your techs, usually the youngest and most computer literate, and get him using the system. Before you know it, each of your techs will have an Amazon Kindle in their toolbox that they use to do inspections with. I know if I told my techs that I was no longer going to use the system, there would be kicking and screaming to deal with and my advisor would try to have me put to sleep.... I'm happy to give you an online demo with live info from my shop if you'd like. Just let me know and we can set up a time that works for us both.

- 21 replies

-

- Mulitpoint process

- Workflow

-

(and 2 more)

Tagged with: