Wheelingauto

Free Member-

Posts

152 -

Joined

-

Last visited

-

Days Won

20

Content Type

Forums

AutoShopOwner Articles

Downloads

Blogs

Gallery

Profiles

Events

Store

Links Directory

Shop Labor Rates

Community Map

Everything posted by Wheelingauto

-

I think a lot of shops are falling behind very quickly. I will take the difficult cars, if they have symptoms we will figure it out. Yes, I might loose a few dollars along the way but I would rather do that and show the customer I am the shop to go to and keep my guys sharp. I am also getting in most cases paid along the way. The most important part of this is to let the customer decide how they wish to proceed and keep them in control of the dollars they spend. Stop, get more money until they don't wish to proceed. Keep in mind my shop is viewed as more of an upscale place, we do not quote prices over the phone and have no menu pricing of any kind, we run no specials so we get very few shoppers though our doors. They are usually scared off by the up front testing/inspection fees. If someone has a problem they truly want to figure out we will certainly help them try to accomplish that.

-

Customer's buying their own parts

Wheelingauto replied to Jonathan Ganther's topic in Pricing, Discounts, Labor Rate

There is at least one very successful shop I know of who marks up parts minimally and charges for actual labor times taken. I would assume the rate is higher than the traditional model. The problem with allowing customers to bring in their own parts is parts quality period. They dont know what is good and what is not. If it becomes that big a problem offer to supply parts at near cost (obviously you could negotiate a little back end money) and just raise the labor rate to account for it. In the end, same dollars, same level of service just different model.- 115 replies

-

- 1

-

-

I hate the idea. But, if it allows you to work on more profitable work and you have enough of it, I suppose it is ok. But........ Most of the time we cannot figure something out, it is due to a disappearing symptom or lack of information from the vehicle. These are the cars I am getting better at saying this is what we've done and these are the results. At this point I can guess or wait for the symptom to become more apparent but unless you want to spend more money I cannot go further. And then LET THEM make the decision. Most of the time they will come back after they experience it again and they can give us more info. The real reason I hate it is for psychological reasons. You see we work hard to become the answer to anything automotive to our customers. This way they are more apt to spend every automotive dollar they spend with us, we will be far more successful the more we can accomplish this (known as first position). By sending them away they may find better service (not likely but possible) we've admitted there is someone better than us and we may just create a different position for ourselves. While most aftermarket shops are in second position anyhow it might work, but I also attribute that second position adds to the ebbs and flows of business as we grow. I would try to figure out how to capture more testing dollars when I can and when necessary let the customer chose to wait or go elsewhere on their own. I am assuming this is unique diagnostic issues and not training issues so if you cant do it they probably cant either.

-

`Scott This has been discussed and there are better ways to go about it. First off, sell tests not diagnosis. When you go to a Dr they test things...they evaluate the results of a test or tests and may come to a diagnosis or if the tests come back negative they dont....but they still charge. We, like you hold ourselves to a pretty high standard and sometimes will spend more than the allotted time...like you we are trying to figure out better ways to charge and present it so the customer gets value. When we present the customer with the initial testing fee we state we will stop and contact them with the results. A sample of what we might report would be we've scanned the computer for codes, we retrieved a poxxx code which relates to this system. We've performed multiple tests to the components of this system and all tests have passed. At this time we do not have a direction to go in. We can clear the codes, return the vehicle to you and when symptoms arise we will then be able to proceed with further testing -OR- we can attempt to get the symptoms to occur while the vehicle is in the shop. This will require driving blah blah blah and so forth and so on......and the cost to proceed with that will be $xxxx. At this point you should advise them what you think is the best route to take. To me it can be like tracing a shorted wire. We don't know how long it will take but we will go about it in the most logical order and you (the customer) will control the process by setting the dollar limit (with our suggesting a range) that we will not exceed. Let them decide how important it is. In my early years I used to allow customers to control things (they will let you donate hour upon hour to find their problem) but realized if is is not important to them (they are willing to pay me to find the issue) it is not important to me. As much as we try to control the loss of time there are still situations where a little leaks out....

-

Customer's buying their own parts

Wheelingauto replied to Jonathan Ganther's topic in Pricing, Discounts, Labor Rate

First off I hope they were the right parts...actually fixed the problem. Secondly there is the aspect of a maintenance repair. Becky Witt often used this example. If a customer went out and bought all Honda parts for a timing belt/water pump replacement with the intent to do it themselves only to find out it was above them. Now, what? Junk parts... nope...that is most likely an exception to the rule. I think if I were to get that call I might just take my hourly overall gross profit average per hour from the last year and quote the job at that labor rate explaining how I came to that rate and at that point I would warranty it. If they went for it I am ok with it...but it is the rare exception. MOst of the time it's cheap fu%*s trying to save a buck.- 115 replies

-

Customer's buying their own parts

Wheelingauto replied to Jonathan Ganther's topic in Pricing, Discounts, Labor Rate

In my mind it is a straight forward situation where a vehicle owner is trying to circumvent the proper steps in solving an automotive problem most of the time in an attempt to save money. Asking "Do you want me to put on the part of fix the car" can be taken as a challenge and also arrogant. Obviously they want the car fixed and are hoping the part is the answer, if it doesn't they will try to hold you responsible. More importantly if you entertain this sort of thing you are giving up control. But they have no facts to work with. They have 3 different prices. If they do happen to select you what basis did they have to make the decision?!? And most of the time after you've wasted time estimating up some sort of repair they say thanks and hang up and go away. You...just wasted valuable time entertaining a consumer when you could have been paying more attention to a customer who's car was in your shop. If the only value you have to win a new customer is giving stuff away you have BIG problems. No, we don't recommend it...we insist on it! We insist on testing or inspecting to find the root cause of your complaint and recommending a course of action that will effectively, efficiently solve that problem completely and we will stand behind it with an exceptional warranty. If you don't like our findings, don't want to afford our course of action that is ok, you can go about your day after paying us for the time we spent analyzing your problem. I love the thought we should work for free for an opportunity to get paying work... FREE BRAKE INSPECTIONS.....whats the incentive to tell them everything is ok? Cause you're the last good guy around...lol, until you are starving, then maybe those brakes dont look so good.... Free code checks... hopefully we'll get a car in the bay and then we can get paid. BS! I say you can all go work for free. If I am going to work for free it will not be to subsidize someones automotive ownership costs. I have value, I am a professional, I get paid for my expertise. If you wish to attempt to strip me of that expertise you can go elsewhere.- 115 replies

-

Customer's buying their own parts

Wheelingauto replied to Jonathan Ganther's topic in Pricing, Discounts, Labor Rate

When you allow consumers to dictate how you do business you loose. When they come in and say I want this done to my car the first question must be what are you trying to solve and the appropriate inspect/testing fee should be quoted. You may get push back but who the hell cares..Pass on it if they dont want you to be the professional.- 115 replies

-

- 1

-

-

Another shameless pitch.....lol

-

This is why these forums are quiet, not really active, and lame IMO. This is not about shops discussing issues and solutions or new ideas. Every post has some alleged Guru pushing their agenda so they can augment their social security income. They prey on the weakness of the inexperienced, new or struggling auto shop owner who needs car count with great ways to get cars in the door, and work the opportunity which usually ends up with high effort, high stress and little to no profits. If they really wanted to make money they would open up their own shops, prove the concepts by having millions annually in sales, 20% plus in profits all while sitting on the beach and also taking a nice paycheck when in the office.

-

The vendors who are my current suppliers are an AC Delco/Motocraft warehouse, World Pac and my local Bumper to Bumper store. I have no idea what is available to you locally but my thoughts are that you need to spend your time not attempting to fix manufacturing problems but spend it finding suppliers who can get you quality parts. Warranty? I am curious why discussion is what warranty a supplier has? Any supplier I have has some sort of program with a warranty attached. Bumper to Bumper has a 2 year nationwide warranty. Great if they break down more than 50 miles from me, but if they do not and I have to fix it they pay up to 3 hours and a discounted rate and supply a new part. I dont have time to chase labor warranties. IMO you will waste a lot of time chasing down discounted labor dollars that could be spent chasing down retail labor dollars. When you do a job and give a warranty to the customer, who's warranty are you giving, yours? or the vendors? We offer a 3 year/36k nationwide warranty on all of our repairs. We do this because we do things right, we don't cut corners and we use quality components in our service. Our warranty costs are built into our pricing and we have less than a 1% warranty rate and most of it is customer satisfaction anyhow. I have not written a labor claim in years and I don't plan to. When I have a part that fails I usually get a new one no questions asked. My vendors know how I do business and I've already told them what I expect if they would like my business. I take care of it and move on. When I run into a manufacturing problem I may tell my vendor about it but if my guys dont like something we find a new line to deal with. Keep in mind the cost of a line that we like is not put up against a line we dont. For instance of Centric brake parts are 20% more than Wagner but we have next to 0% complaints or defect from centric and 10% from wagner WE DONT USE WAGNER. We also dont complain to the vendor who sells Centric that we can get shit parts a lot less. We do negotiate discounts from our vendors if we are loyal to a certain line.

-

As a technician you are great at solving problems. Now, put on the owner/manager hat and start solving business problems. We are always going to run into problems when dealing with aftermarket parts. What you learn and the decisions you make will cause a significantly different outcome. I am not a tech, never have been. As I read about the issues you describe I think of solving them differently. Dorman?? Junk...absolutely last option. AAP....deals in a lot of junk IMO. Time to find and create relationships with quality vendors. 3 month labor warranty at half price and ALL the paperwork to collect. hmmm...it seems to be if you cut your prices in half and had no warranty you'd be in much better shape....not a consideration though? Then who the heck cares about a labor warranty...(BTW it's built into their pricing) As a tech you should be billing out somewhere between $3-$4 an hour. As an owner you need to figure out how to keep the tech billing....is the tech calling the parts company trying to get them to fix manufacturing issues? Thats a LOT of time wasted by the tech....owner needs to get techs head on correctly. You make it sound like quality parts are more difficult to obtain, if so the repair process needs to be streamlined to account for it rather than wasting all that time trying to push the boulder uphill. Order parts ahead of time, get a couple of loaners so customers can wait for the right parts to show up..... there are a lot of creative ways to solve the problems other than doing the same ol same ol....

-

If I had to do it today I would figure out how to do it electronically but we have been doing it so long until I find a bullet proof way I will not change. Everyone walks in and punches in on a time card for work. That is how we capture available time. When they start working on a job they punch in on the written work order. When they are done or waiting they punch out. When the advisor is writing the ticket up they calculate the actual time and put it in the software. Sold time is calculated when the job is estimated. The guys/gals will be resistant at first but you have to sell them on the fact this will let you improve things and in the end it will make them more. They automatically think it will be punishment. I have a lube tech, 1 apprentice, 1 b tech and 2 lead techs. While my productivity numbers are not the best< I still know where we are as a group. Because I have a large facility we have very good efficiency numbers. You dont really have to worry about who you stack up to or against, you only need to improve against yourself and everybody wins. If you dont measure you cant diagnose and fix it or improve it.

-

This is an interesting discussion for those it could help and the tools they need to achieve them. In order to manage a business we need the correct tools. The smaller the business the less tools we need. But as a business grows, more tools and measurements must be used to diagnose problems within the business. Tech time management as originally taught by RL O Connor refers to 3 different measurements. Sold, actual and available time. Sold time is the amount of time you allot to the technician to get a specific labor function completed. The dollars and cents do not matter for this calculation. Only tech gets one hour to hang said part on car. Actual time is the time it actually takes the tech to hang said part. Available time is the time the tech is onsite ready and able to perform job duties. Why do we need to track all 3 instead of some sort of hybrid. To diagnose problems. Tech Efficiency The technician for the most part is responsible for this. IF he/she focuses on the job at hand, properly tooled and trained should be able to bill out many more hours than actually working on cars. Sold divided by actual = Efficiency. A good tech can easily be 150% efficiency. Productivity The business is mostly responsible for productivity. If the tech runs out of cars to work on he can not be productive. We are all human and need a few minutes throughout the day for non productive functions such as piss breaks but if we have enough cars and jobs get sold correctly, we can be 90% productive. We CANNOT BE MORE THAN 100% PRODUCTIVE. 8 hours worked vs 8 hours actually working on cars. Actual divided by available is productivity. 90% is a high mark IMO. RLO used to have non productive categories for a tech to punch in and out of when not working on cars in order for us to measure unproductive time. If a tech was on the phone calling parts stores he is not productive. Now, of you want to talk dollars, like how many dollars for diag procedures or how few dollars for an oil change we are talking about effective labor rate. At the end of any day take all the labor dollars for completed work and divide by total available hours and you have effective labor rate. This is solely a management function and the tech has not control over this. But I am off subject. Why do we need to track these metrics, to properly diagnose a malfunction. You may think you know by gut or watching, can be very effective for smaller businesses, but truth is in a larger business metrics dont lie. We have all heard at one time someone bellyaching we're not making money, all my techs are slow, dont know what their doing etc. Then we go look at the layout of the building and find out to do one job the tech has to walk to both ends of the shop to retrieve something he needs frequently, or does not have the tools he needs with him and back and forth to the box which is 3 bays away. Of has to go to the parts room to get the only scan tool for whatever reason. OR..... the tech is always being interrupted to do something other than fix cars. Tell boss I dont have an oil filter in stock but boss is busy talking to wife about weekend plans (or customer or whatever) and tech grabs a smoke break and a phone and calls Ed down at the parts house, after 10 minutes of BS finally order the oil filter that should have been in stock but was not there. Or take a customer home because management could not do it. Waits for the last part to fix that car and there are no more cars to work on or no more bays to work in. If you measure and monitor these figures and then spend the time to make corrections as necessary you will achieve the net profit goals discussed by some gurus. It is easily attainable. I can go on and on about it but it's time to go home. I hope this benefits someone.

-

This is where this discussion becomes lost. This discussion needs definition of efficiency, productivity and other terms being thrown around so those who need to understand it better might. Instead it scares some who dont feel they can get to some numbers and others who are well above. For instance, a seasoned tech with plenty of space should be significantly above 120% efficient. Overall a shop needs to consider the talent they employ before they can assess a goal for efficiency and productivity. Above 90% productive, incredibly hard to do and even harder to do consistently. This is by my known definitions of the terms though.

-

We bought 2 Fujitsu fi-6130 scanners about 8 years ago. We scan 100% of everything and have a 2tb drive in our server which is also backs up into the cloud. We currently have 51 gig's of data. Neither scanner have given us any issues. We created and use a windows folder system which works for us. I can retrieve any document from my computer, the scan computer or my bookkeepers computer. The advisors can look up old notes, invoices and parts receipts from their work stations. If we did not have this system we would have at least 10 filing cabinets. My bookkeeper scans for maybe 15-20 minutes a day when she finishes her paperwork. I would be happy to share more if needed.

-

Open a new shop or buy existing shop

Wheelingauto replied to carjunkie's topic in New Repair Shop, Partnerships, Bank Loans

Yeah, but I can make Florida to the Bahamas and back a day trip....... -

Open a new shop or buy existing shop

Wheelingauto replied to carjunkie's topic in New Repair Shop, Partnerships, Bank Loans

-

Open a new shop or buy existing shop

Wheelingauto replied to carjunkie's topic in New Repair Shop, Partnerships, Bank Loans

It appears as if I was not clear. 20% plus add backs equals 500k not 500k plus 20%. Got it on the profit on income taxes. Good luck in your search. -

Open a new shop or buy existing shop

Wheelingauto replied to carjunkie's topic in New Repair Shop, Partnerships, Bank Loans

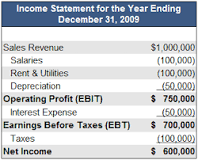

My 20% net number is high? In most places I guess you're right. Interesting fomula and one that does not clearly make sense to me. Profit on income taxes??? I have heard 2-3 times EBItDA Earnings before interest, tax, depreciation and amortization. Using this formula and from what I've heard the bigger the organization the higher the multiplier. Take a company that is doing 2 mil at 20% net. That means 400k profit plus the addbacks which easily can be a total of 500k (most likely more). If that can be substantiated the purchase price should exceed 1.5 mil. agreed or am I still not thinking right? Ignore the attachment -

Open a new shop or buy existing shop

Wheelingauto replied to carjunkie's topic in New Repair Shop, Partnerships, Bank Loans

Define SDE. 2 million sales with 20% net = 400k plus add backs such as depreciation. 400k x 3 = 1.2 mil and that would be low considering what it takes to run at that level again IMO. Where do you get 400k - 600k purchase number?