-

Posts

127 -

Joined

-

Last visited

-

Days Won

20

Content Type

Forums

AutoShopOwner Articles

Downloads

Blogs

Gallery

Profiles

Events

Store

Links Directory

Shop Labor Rates

Community Map

Posts posted by CAR_AutoReports

-

-

We have some more updates coming this week, but for now... we have made a 2 and 1/2 minute video showcasing just how much information you can get access to from our Service Request page. This page helps you get complete access to all necessary customer and vehicle information without having to leave. It also showcases the importance of capturing accurate information once, so it saves you time with each repeat service.

-

1

1

-

-

Whether or not we realize it, each shop has a similar workflow process. Like many areas of life, we think that we are all unique in our business strategy. However, reality is we are all very similar, our differences lie in management styles. Our attitude and approach, from employees and customers, defines how we achieve success.

- Check In

- Inspection

- Estimate Building

- Customer Authorization

- Work In Progress

- Completion

- Follow Up

The process, is often hijacked by two elements. The first element is service center employee(s) and their attitude(s) and the second element is the software your business uses.

Your employees are your team, and that’s exactly the best way to approach your business. When you look at employees as team members and not as just “the new guy/girl” or “Jack the mechanic who never combs his hair”... everyone’s attitude begins to change.

Being a part of a team is a mindset that everyone ‘shares in the responsibility’, everyone is accountable for their role and if one person fails… everyone has failed. This mindset is used to build all types of companies, some of which end up being valued into the billions of dollars. Teams help each other pick up the slack and work with one another to get through personal and professional barriers.

The most important thing to remember about the team, is that everyone can have a bad day, week, month or even months. We are all human and too often we forget everyone is going through something. The team element opens the door to communication among the facility and if people are comfortable enough to communicate, they are open to moving past whatever ails them. We are all too quick to give up on someone we have invested an immense amount of time and energy training to our standards. With the right team, dedication is matched on all ends, resulting in happy customers that not only return... they refer. Which lowers acquisition costs and keeps business growth healthy.

You can read more about team building here and we also encourage you to search for ideas on team building and how to achieve the optimal team at your auto repair facility.

This article originally published in CAR's News Section

-

Hi everyone, have a bunch of updates to share with everyone today.

So this month we have:

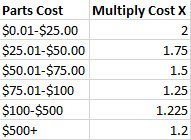

- Price Matrix: Fully enabled and functioning.

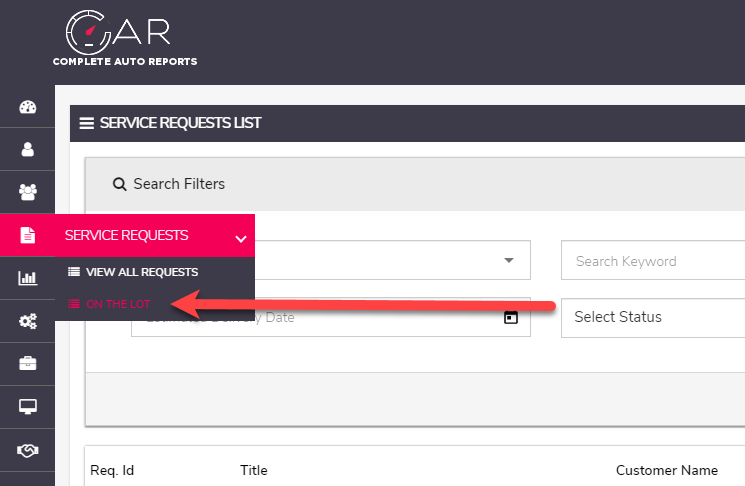

- On The Lot shortcut in the left menu: Quickly filter search results by vehicles marked "On The Lot".

- Smart Batch: Now have the ability to see what items meet smart batch criteria. See if you have any in stock, and replace a current part on the service request with a smart batch part.

- Search Filters: Can now filter search results through all service requests. Search Filters are: Business Name, Customer Email, Customer Name, License Plate, Part (by part number) Request ID, Title, Vehicle, VIN

- Photos & Videos Are Now Live Updated: As you fill out recommendations and the service request, any photos or videos taken are now automatically updated to the customer as they are uploaded on your end. That way, if a customer logs in, they can see what you're doing as you're doing it... without waiting for you to send it to them. It allows you to mitigate phone calls like, "Well can you tell me what's going on?". Sure, if you login to CAR, you can see exactly what we're doing and as soon as we determine the root cause, we will provide you with the estimate to review.

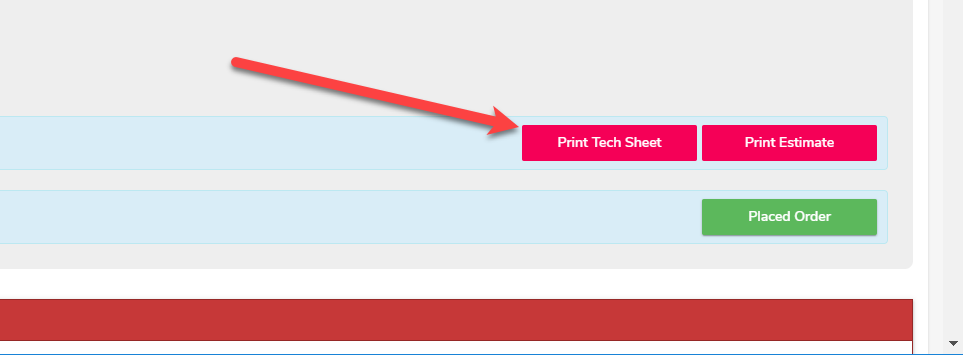

- Print Tech Work Sheet: By demand, many customers have asked to be able to print out work sheets they can leave on the vehicles so technicians can grab and go, we have now enabled that.

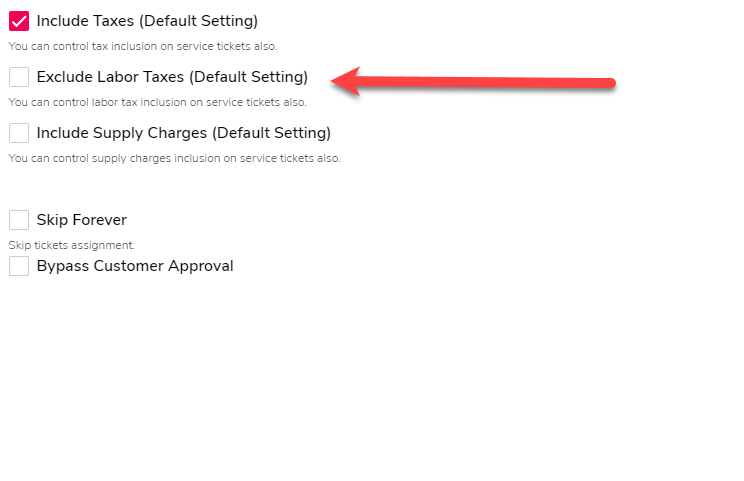

- Exclude Labor Tax Only: Some states only have tax on labor only, while others have parts and labor. We have allowed a function to eliminate any tax calculations based on labor.

- Quick Start Guide: Want to tinker on your own time? We have now made an 8 step guide on how you can get started on your own., with CAR. We are also incorporating this into the system dashboard along with other tutorials to help you get started doing things and training employees with minimal downtime.

Repair Link Access is available through our console for members who ask for it. We can NOT pull information back, but you can build estimates in Repairlinkshop.com right from the service request and submit orders. For the time being, you need to then manually enter the parts if they are already not in the database.

Future Development:

We have some items coming up in the next few weeks that will further enhance the system and it's use. Among them, prevention of duplicate tickets being created and the ability to copy a job. As we button those feature sets down, we will be sure to let the community know. Copy jobs will really shine with parts searching capabilities. We are also working out plans for Quick Quoting features and many other minor features that will really simplify the process and continually shave seconds of time that will add up to hours and days at the end of each month.

Want to try with no commitment?

We are offering free upgrades for any plan we have for up to 3 months to any shop that is willing to learn how seeking customer authorization in a structured fashion, which will lead to a serious increase in approvals. We have grown our business by 50% in revenue with this software, in just under 3 years. All because we let the process dictate how the business runs. This isn't a gimmick, this is how to conduct business in the 21st century. Limit your liability and wow your customer with professionalism. Only with CAR.

-

Hey everyone, an update on April Fools that isn't foolish.

This Month's Progress:

- Purchase Order Numbers: The CAR ID now transfers to vendor invoices done through PartsTech as the PO number. Making items very easy to identify when ordered through the platform and they show up at the door.

- Diagnostic Time Option When There Are Rejected Jobs. When closing out a service request that has rejected jobs, the system prompts you to add diagnostic time. The choice is yours ultimately, but it does two things. Acts as a reminder to actually get paid for your time spent, adds the diagnostic time without you having to go back in an edit the ticket.

- Smart Batches. So we are finishing this, but the premise is live. You can take a batch of parts that are interchangeable and make a smart batch out of them. The easiest way to explain this is through an oil filter. There are a myriad of oil filters that are interchangeable, or sometimes it's the same oil filter with a different part number. Like PF47 vs PF47E. So we designed a system to allow you to tie in the interchangeable parts to work with local inventory. In the photo below, all of those oil filters act as a PF47 when adding then to a service request. So if you added the Motorcraft FL321 and didn't have any in stock, it will tell you that you have the 72 132WS Bosch Filter in stock that is the direct equivalent.

- Duplicate Part Number Reduction. When adding parts to the local database, it autofills now, so there are less opportunities of entering in duplicate part numbers. Like entering in a part number, 28113-2S000 with the dash vs 28113 2S000 or 281132S000. Just a method to keep the data cleaner, which saves everyone time and money.

Minor Fixes:

Reduced the size of the "snack bar" to enhance desktop and mobile experience.

Currently In Beta:

Parts Price Matrix. This has an element included in it that was provided to us by someone who believes in our product and process. This individual provided a mathematical calculation that completely eliminates the sharp drops from Price Ranges. We are so happy with his assistance here, that we can't wait to show you the curve CAR will provide your business in profit, versus the jagged edge drops.

Future Development:

As we continually close the gaps of features we are missing for larger scale facilities, we are approaching crossroads where we are enabling features based on data that no one can presently do. So we are working on A LOT of things we can't necessarily talk about. What I can say, is that in about 3 months time... you'll be able to replicate a complete service invoice... from your cell phone... while checking in a vehicle... in less than 60 seconds.

What we can talk about:

We are working on a method to open www.repairlinkshop.com within CAR and submit orders and pull back parts data. We expect to be in beta around June with this.

We are working on a method to open repair information within CAR, from Identifix to start. This is a slower moving boat because of the lack of cooperation from data providers in the industry. But we have found some ways to at least get the ball moving with Identifix for now.

-

1

1

-

Hey @RMF, we are sending you an email with some information about our platform. Thanks for the interest and the kind words.

-

1

1

-

-

Thanks for the follow up. Greatly appreciated.

Do the replacement sensors look like the OE ones?

Autel TS508?

-

The best advertising comes in the form of referrals, which are usually free but don’t happen overnight.

Advertising is perhaps the most confusing part of owning any business, not just an auto repair business. Advertising is, to take your marketing materials and broadcast them in mediums where you anticipate your target audience. The internet has drastically changed advertising as most understand it. We used to think of advertising as the “yellow pages” and newspapers. However today, the yellow pages comes in many different forms these days. All of which promise you the world and few of which will deliver.

We recommend taking a broad approach to advertising to test what will draw in the most amount of new business to you. When thinking about how to advertise for your business, below are some suggestions to consider. First, establish a yearly/monthly budget, then to execute a plan. The most important part of your plan is to follow through on asking your new customers how they found you, that way you know what advertising is working.

Our advertising model assumes you have a few things in place, as we also discussed in Part 2: website with contact module, Google Business Page, and a Facebook Business Page.

We are firm believers that Google’s vast grasp on search is what makes it the king of advertising for now. Most people start their searches on Google, and if you’re not on Google maps and your website hasn’t been crawled by Google… you may not exist. We can argue this until the cows come home, but the truth is they hold a grasp on nearly 80% of all search in the US. Picture 10 people searching for “auto repair in my town”, nearly 8 of them are using Google. It’s much easier and fruitful to advertise to 8 out of 10 than 2 out of 10.

We are going to assume you have a $250 budget, the starter plan would be something like this:

- Google Business Page – Free

- Facebook Business Page - Free

- Adwords Campaign through your Google Business Administration Page – Budget Dependent - $100 per month recommended

- Local Paper Advertising – Prices Vary – Assuming $100 per month

This leaves you with $50 left over. Personally, we recommend a service called Yext, however we are unsure of their price these days as they have gone into a "Demo mode". This means they likely introduce you to the price after you’ve demo’d their product. For a one location auto repair business, we believe their estimated price may be over $600 a year, which kind of busts the budget a bit. But once you see how much time their platform can save you… you may reconsider.

Yext does a few great things that stand out:

- They broadcast your correct business information to well over 100 directory systems, including Google and Facebook.

- They also allow you to make business updates from their platform and broadcast it to all the directories in the network.

- They manage your inbound reviews from your customers on all those platforms and immediately inform you when you receive them.

- They allow you to broadcast messages of specials you may want to promote.

- They link your business website from 100 different directories, instantly giving your business credibility online.

- The most underrated thing they do… is save you time from trying to log into 100 different directories and fix errors, omissions, and broadcast them all at the push of a button. Can you imagine the time it takes to create 100 different accounts and to regularly check and manage them? We did, so we tested Yext at our founder’s facility and have been a subscriber for well over 5 years now.

This article originally published in CAR's News Section

-

I'm assuming that in using their sensors, you clone the original number onto that sensor so the vehicle just looks for that same signal?

Look forward to learning about how you made it through. My situation was for an insurance claim and I had to use OE everything and have receipts for it. Using an aftermarket unit was not an option.

-

You can't program these at the moment with aftermarket tools, dealer only.

We paid to have one done within the last 6 months on a customer's vehicle at our shop in Linden NJ.

-

1

1

-

-

Migrating from anything can be a headache, the best approach to take is to evaluate what you presently do, very thoroughly.

Start with:

How many machines are used with the program?

How many employees?

Do they require logins?

Expand to:

What are the things you do daily that you take for granted? This is a hard one that requires a team effort to answer accurately.

For instance: You clearly check in a vehicle and check one out every day, at the least. What's involved in that?

How does your new system handle that?

Who has to learn what to perform their role?

Other than working through the questions up there, the easiest way to learn a new system is to do the following:

Plan on using both systems for +/- 120 days in unison. What does this mean. Well the first 30 days, focus doing things as you normally do, but at the end of each day, enter the customers that you serviced that day in the new system, along with their vehicles. Notice anything different? Anything you need to adjust to? Anything that has to change your train of thought?

Run that for 30 days or as long as everyone is comfortable doing it. My suggestion is to allow all of your employees to perform these basic tasks to get everyone used to the new interface.

Next 30 days, time to recreate invoices for the next batch of services. Rinse and repeat the steps above.

By the 60th day, everyone should be accustomed to how things works, what the strong points are and what the weaknesses are. On the 61st day... start with the new system entirely for just that day. Evaluate your entire process at the end of the day and see where the team is at. If everyone is comfortable, keep moving till you hit a hard enough road block that causes the world to stop spinning.

By the 90th day, your entire team should be fully transitioned to the new platform. But the 30 days cycles are arbitrary and you should work with your employees to transition. Having them on board is what makes this easy or hard.

Changing platforms is actually really easy when it's broken out into steps. It's the businesses that do a full hard turn that have a hard time and fail to adapt to better software. It's a time when your leadership qualities matter the most, because in the end... you benefit the most from a better software platform.

-

This Month's Progress:

- Plate To Vehicle Information - Fully functional

- Reporting now exports: Year, Make, Model, License Plate. Benefits if this allow you to use excel to understand your customer base a little better. Will eventually be built into our reporting tab, but giving raw data access for now.

Here is one set of statistics you can perform with this data:

- $0 balance is auto marked as paid

- System updates refresh cache through a message when logging in.

Still Working Through:

- Price Matrix - Linear - Expected by end of this month. Delayed by some parts and inventory tasks to enhance operation.

- Diagnostic Time Option When There Are Rejected Jobs. Currently testing, live likely within 14 days.

- Learn While You Use - 3 out of 6 walk through tutorials in testing phases.

Other Current Enhancements:

- Parts redundancy elimination - We're working on several items that really help shops control their parts information. Working to: group exact parts together & eliminate double+ part numbers.

Vendor | Sponsor Enhancements:

- We are building a portal that will allow vendors or sponsors to reach their customers through our portal in an efficient and elegant manner. This is something completely new to this arena and was driven by a partnership we are presently working on. However, it's going to be a game changer when it comes to Vendors or Sponsors with features they want their customers to have access to through their Shop Management System.

We've also got a lot of surprises up our sleeves from user generated suggestions. All things we are working on for 2019 as it continues to move through.

-

1

1

-

J Larry,

Thank you very much for that. We have ideas for integrations and Zapier has crossed out path. However, since we want to be able to guarantee security and through native integrations, things start to get tricky when you are passing information across several layers. So we noted that we could potentially use third party integrations, but shelfed it temporarily to work on Inventory & Matrix. As the first quarter finishes up, we will be back into integration focus, starting with Payment providers and moving back into other parts ordering systems.

Ricardo

-

On 2/10/2019 at 9:49 AM, autoguy said:

Any other parts integrations outside of partstech? Nexpart, IAP direct or any parts suppliers portals directly like worldpac? partstech is just a third party software that uses connectivity from systems like a nexpart or IAP to connect.

We have plans to expand the integrations later on this year. Since our approach has been unique from the start, we focused on making the process as seamless as possible first, then the integrations second.

A lot of those companies aren't very helpful with their integrations and we tried to work to get them on board initially. But after being continually ignored we focused our energy on the core product.

-

My largest competitor as a shop, is also one of my greatest allies when I am in need.

Competition is a necessary demon and without it we all sit still and stagnate for way too long.

-

2

2

-

-

To anyone who has been following our progress, we've been really hard at work getting things moving:

In the last month these are the features and changes we've made:

On The Lot.You can now mark a vehicle "On The Lot" and it's to be treated as... "In My Possession". It helps unclutter the service request que considerably and allows you to quickly wrap your head around what's going on at the moment. We are still ironing this out, but the time is saves everyone at the shop here is noticeable to say the least.Inventory is now live.Inventory comes complete with the ability for you to import and export all of your parts through it's own uploading system. In addition to that, parts that are ordered through PartsTech are automatically entered into your inventory and start to count towards monthly totals that help you establish trends in parts you use the most. There's also a functional return que. So if you order a part through PartsTech and remove it from an invoice, the system asks you if you are keeping it in inventory of if you are putting it in the "Return Que", aka the return shelf. This also has it's own ability for you to mark parts as returned to a particular vendor, even allows for you to upload a photo of the return ticket the vendor leaves you with.Inventory also comes with a "tagging" system. The tagging system will allows you to basically organize your inventory according to your business. So you can label your shelves like, "A2B". Shelf A, Row 2, Column B. Maybe you have a particular high priced part in your office. You can tag it with "Office". The possibilities are literally endless and it's a simple system to implement.Employee management is enhanced.We have built in some features to better control employee timers and control the session of each individual who is working on filling out tickets.Reduced repetitive steps.We have added functionality that auto fills the state, timezone and customer type for each customer as well as the vehicle license plate state. Saving you a few seconds each time from having to select them.Consolidated closing of service requests.A work in progress to help speed up some of the quicker/shorter service requests. There are other additions to this coming this month as well.On the docket for this month is:- Price Matrix - Linear

- Plate To Vehicle Information

- Diagnostic Time Option When There Are Rejected Jobs

- Learn While You Use - A help feature is being built in to help you accomplish basic steps to help you adjust to a new system.

-

1

1

-

12 hours ago, ScottSpec said:

I recommend you talk to you insurance company, and your lawyer. There is nothing you can do to limit your liability. You are just as liable for a customer's part, as you are for a part you purchased and installed. I think you might also find it difficult to offer different warranties for the same part. These are not just my opinions, they have been tested in court.

Scott

I have spoken to my insurance company, they have 0 rules and regulations about customers bringing in their own parts. They did have plenty of regulations regarding me selling parts to the general public and not just my customers.

As for the attorney, I have not spoken to them yet but I have read some of the court documents surrounding the cases. No one can force you to offer any type of warranty for anything. No one can also force you to abide by one warranty for everything you do or sell. There are plenty of companies that sell products that offer 30 days warranties and some that offer 2 year warranties. Computer manufacturers and the companies that sell their parts come to mind.

The law states and has been tested in me taking responsibility for the work I did. It does not and can not tell me how long I have to warranty anything.

Do you install and warranty a used engine from the junk yard with the same warranty you sell and install and OEM engine in the crate from the dealer? Different circumstances call for different rules. This arena, is no different. I also can refuse the right to touch anyone's vehicle, but I am using the approach to turn customers from parts buyers with little trust, to life long customers who trust they are getting a fair deal.

In short, it's not a habit to allow customers to bring their own parts. But if someone who is showing a good attitude is trying to find a way to work with us... we will try to work with them and get them to stop buying their own parts. We've seen this happen in the last year already. But we never do this for first time customers.

-

1

1

-

-

We allow customers to bring their own oil, as long as it meets spec. If it doesn’t, we tell them and offer the right oil or send them on their way.

The legal way around customers buying their own parts is limiting your warranty and liability. Nothing in the law states that your warranty has to be the same for each and every service. So our adoption is, sure you can bring your own parts. But here are the parts you MUST buy the parts we indicate and your warranty is limited and your labor rate is inflated.

That will help you weed through the shitty customers and convert the good ones from distrustful customers of the industry to good customers for you.

I have a very recent example of a customer that I did this with and I occasionally give parts to at cost and make up for it on labor. He’s spent an enormous amount of money with us in the last 4 months and couldn’t be happier with the service we provide.

-

Just wanted to follow up with everyone and let them know that we have implemented a variation of what we discussed here.

We are adjusting the matrix slightly, but our overall prices were raised 8% while raising labor the rate 15.8%.

-

On 12/31/2018 at 1:55 PM, samgoto96 said:

I would like more information on your software also, free and paid subscriptions

.

Hi Sam,

We will reach out to you today and learn about how you do things and how we can help. Thanks for your interest.

-

It's also worth noting that dealers in my area are @ $125 for Japanese $155+ for German and $100+ for domestic.

In most circumstances we are at least 25% cheaper than the dealer. That gap needs to be closer to 10% if you offer dealer like amenities such as a clean waiting room, loaner cars and pick up/drop off service. Which we do. To maintain those services and grow (hopefully), we need a stable labor rate to allow the flexibility to hire without regret. Standardizing the parts prices is a two fold incentive.

It eliminates a point of contention at the counter and it provides a selling point.

"Our promise to you is to always be fair in pricing of our parts in the age of Amazon. Our parts margins are constrained to help ensure that you receive value with each service here at XXXXXXXX." We are also working on a larger initiative with the entire model, a combination of a membership model with baked in prices for regular service, no frills pricing with dealer level service on maintenance.

-

I am contemplating something more along these lines for price standardization.

In conjunction with that, a modest increase in labor price and an adjustment to our advertising campaigns.

All in an effort to completely eliminate the focus on parts pricing and focus on containing labor and getting paid to reflect the labor needed to do the job in an industry short on staff and high on demand.

-

6 minutes ago, Love The Biz said:

That seems somewhat like how the parts matrix should be, or pretty close to how I already do it, but off a bit. So if you bill actual time, versus book time, how then can you give an Estimate before the repair? If you have a Mechanic who don't routinely make book time, or perhaps run into a snag, removing a part, you already quoted the job? Nothing worse than calling those folks back for more money. And even worse, if they arrive and your bill is higher than your estimate. I have never really had an issue , explaining mark up on parts. I tell them I could never get parts that inexpensive as they are online. I know that Repair Pal, is not our friend. Folks are looking that up, immediately after sending them the DVI. Also now with Napa's Estimator as well. But folks understand I am covering that part, for whatever amount of time, I advertise.

Overbid and explain the overbid and how experience shows we will encounter hardships that are not our fault and will still need to be addressed. We are in the business of doing it once, not twice. With that comes someone who doesn't rush through your job to "just get it done". That takes time and a team.

When I see something major is about to happen to cause a drastic change in price, everything stops and I call the customer immediately.

-

2 minutes ago, ScottSpec said:

Yes, customers will always find something to complain about, and the approach I am thinking about is not without its risks. In fact, what you just asked was the first thing my service manager said to me when we discussed it. We have been moving away from having a posted "labor rate" for a while. We have a "labor rate" that we use to calculate the labor for a given job, but we always present the the total labor for each job to the customer. This makes it a bit more difficult to make an easy comparison. I also find it much easier to address higher labor, then trying to get a customer to understand that my business model requires me to double the price of a part. Labor charges are very subjective, while parts prices are objective. Each of our shops is unique, no one else can offer exactly the same service, and the customer has no idea what it cost to produce the labor. You can easily differentiate yourself, and therefore justify a different labor rate. When a customer tells you he/she found the same OEM part online, for 1/2 the cost, there is nothing you can do to differentiate the part you are selling, from the part found online. You are now in a position where all you can do is try to get them to understand that you have to mark parts up to stay in business. A lot of customers do understand this, but each one has a different idea about what constitutes a reasonable markup, and what is excessive, leaving them feeling ripped off.

Whenever I discuss this idea, I feel the need to add my disclaimer. While I do continue to like the possibilities of conducting my business this way, I still have not tried it in my shop. So, I do also have some serious reservations about it.

Scott

Just had this discussion yesterday at the shop, the exact same retaliation was given on all sides. It's pretty funny actually.

In short, we're still contemplating it, but maybe altering it. Maybe have a more reasonable tier of markup. Like 100% for $25 and under, 75% for up to $50, 50% up to 75% and 20-25% from $100 and up. With a rate drop at let's say $500+ to 18.5%.

And instead of full frontal with the larger labor rate, a more modest bump to make the change less noticeable. So if we were at $95, maybe $115 (domestic) to $125 (foreign), which is still cheaper than local Toyota dealer in this area. But I'm also talking about billing actual time or book time, whichever is greater as often as humanly possible. Precision labor billing is the key we think, with some room for the nightmares we all encounter from time to time.

-

1

1

-

-

14 hours ago, lakesidetire said:

I’d like to know more about your software.

Hi lakesidetire. I'm going to send you a message about it. Thanks for your interest.

Free Simple Shop Management Software

in Management Software, Web Sites & Internet

Posted

I think you’re basing the nature of your assumptions on that of other experiences. Yes we are a cloud based software and yes, we do host and hold all of your “data”. As a shop owner, this element carries a little more responsibility with me than it may with most.

I am not interested in your customer data. I am interested in how to make the platform better for you and everyone else after or before you.

How many desktop applications actually give you your data to access it and do anything with it, in a legible format. Not some secret database format.

We at least make the promise to always export your data in a legible format so it can be plugged into a different system.

You’re also a little mistaken on privacy policy. They are mandated for a reason. If we use your data without your consent in the policy, or worse... use an inkling of identifiable data.... the show’s over.